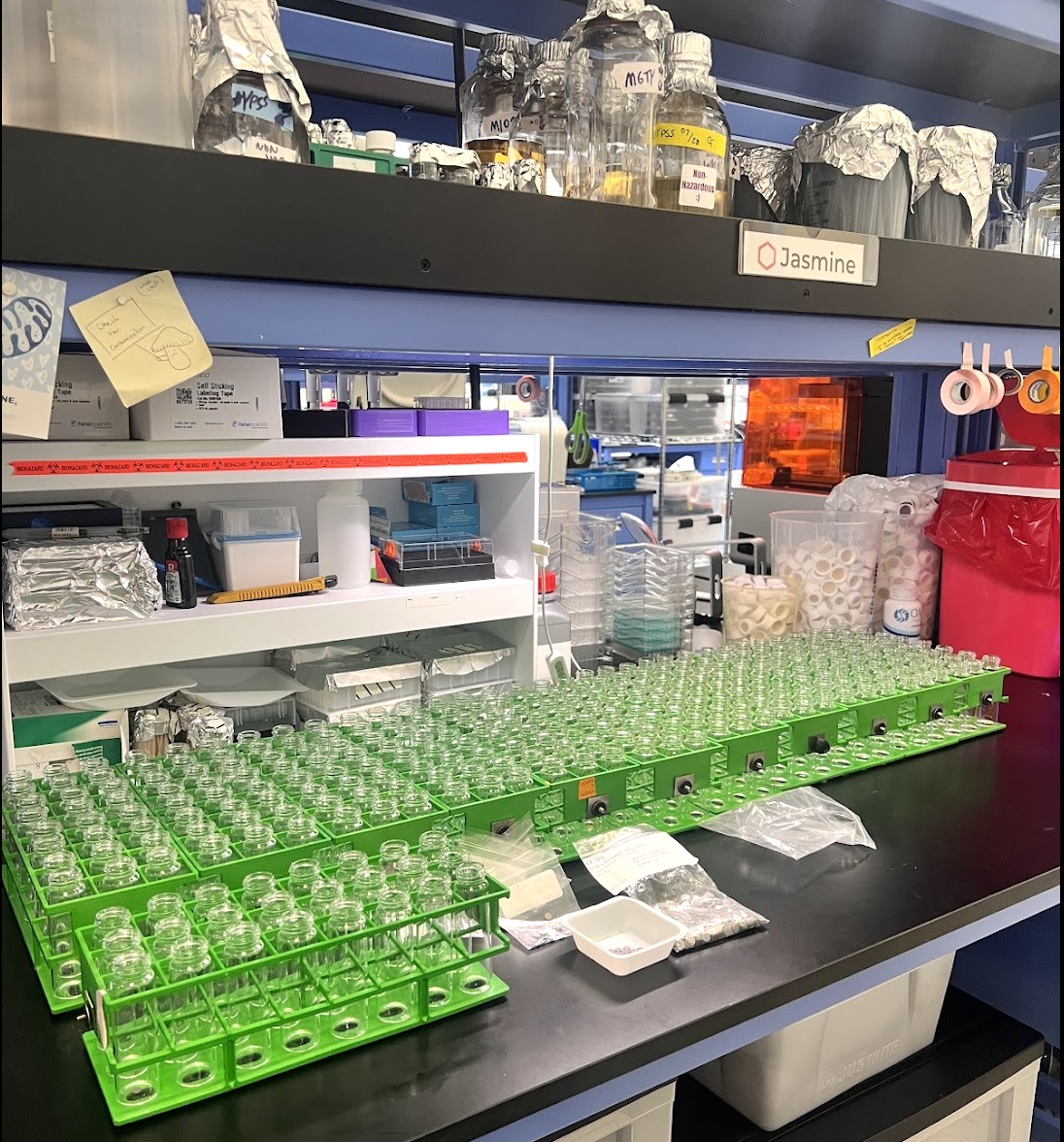

As part of my role, I prioritized safety around lab automation equipment, ensuring that all users could operate the systems confidently and without risk. I trained over 40 scientists and research associates on how to safely use Hamilton robotics systems, emphasizing proper handling techniques and safety protocols. This included step-by-step guidance running methods which I developed for them. Additionally, I replaced HEPA filters on the Hamilton equipment to maintain a sterile environment, particularly when working with BSL-2 microbes. This not only preserved the integrity of the experiments but also protected scientists from potential toxic exposure. My focus on creating a safe and efficient working environment helped foster trust and reliability in the lab's automated workflows

8 examples of Decks I have developed (which are set on a Hamilton robot) and a small description of methods:

Scientist- Centric Design

In my role as a Lab Automation Engineer, I developed over 50 custom methods and editing more than 200 deck images (I’ve included eight examples in the next two slides). These methods were crafted with a singular goal in mind: to create solutions centered around scientists' needs and workflows. Each deck image—the first thing a scientist sees when they power on the robot—serves as a visual guide, showing where to place reagents and which labware to use. Every deck image, unique and meticulously designed, was paired with the Hamilton methods I developed in close collaboration with the scientists themselves.

Through interviews and observations, I tailored each method to align seamlessly with their physical setups, operational habits, and workflows. Beyond functionality, safety was paramount—I thoughtfully arranged reagents and plates to minimize risks, ensuring that accidents like finger injuries in the lab were virtually eliminated. This scientist-centered approach wove together usability, efficiency, and safety, reflecting my dedication to thoughtful design.

Method Development Process

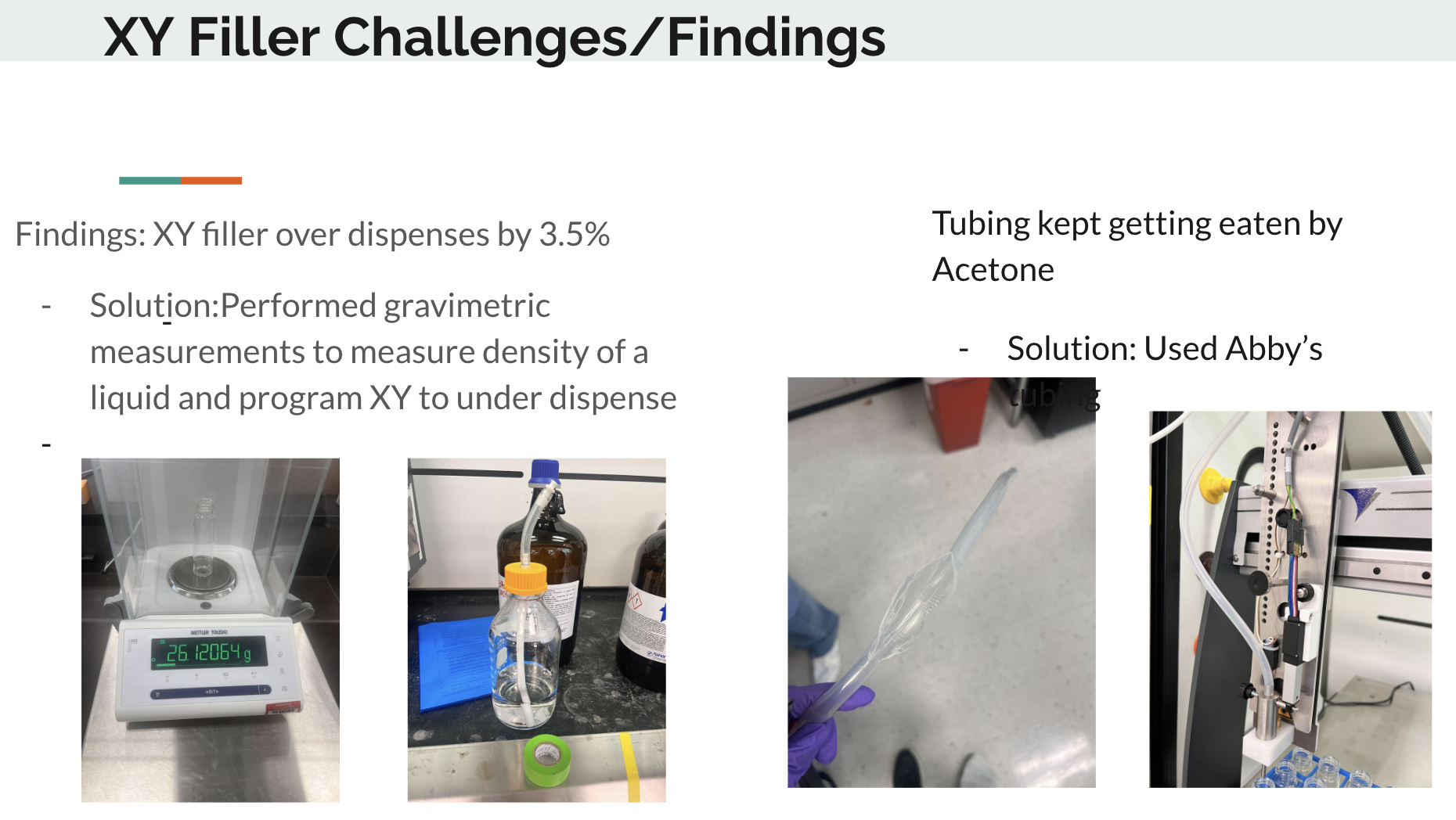

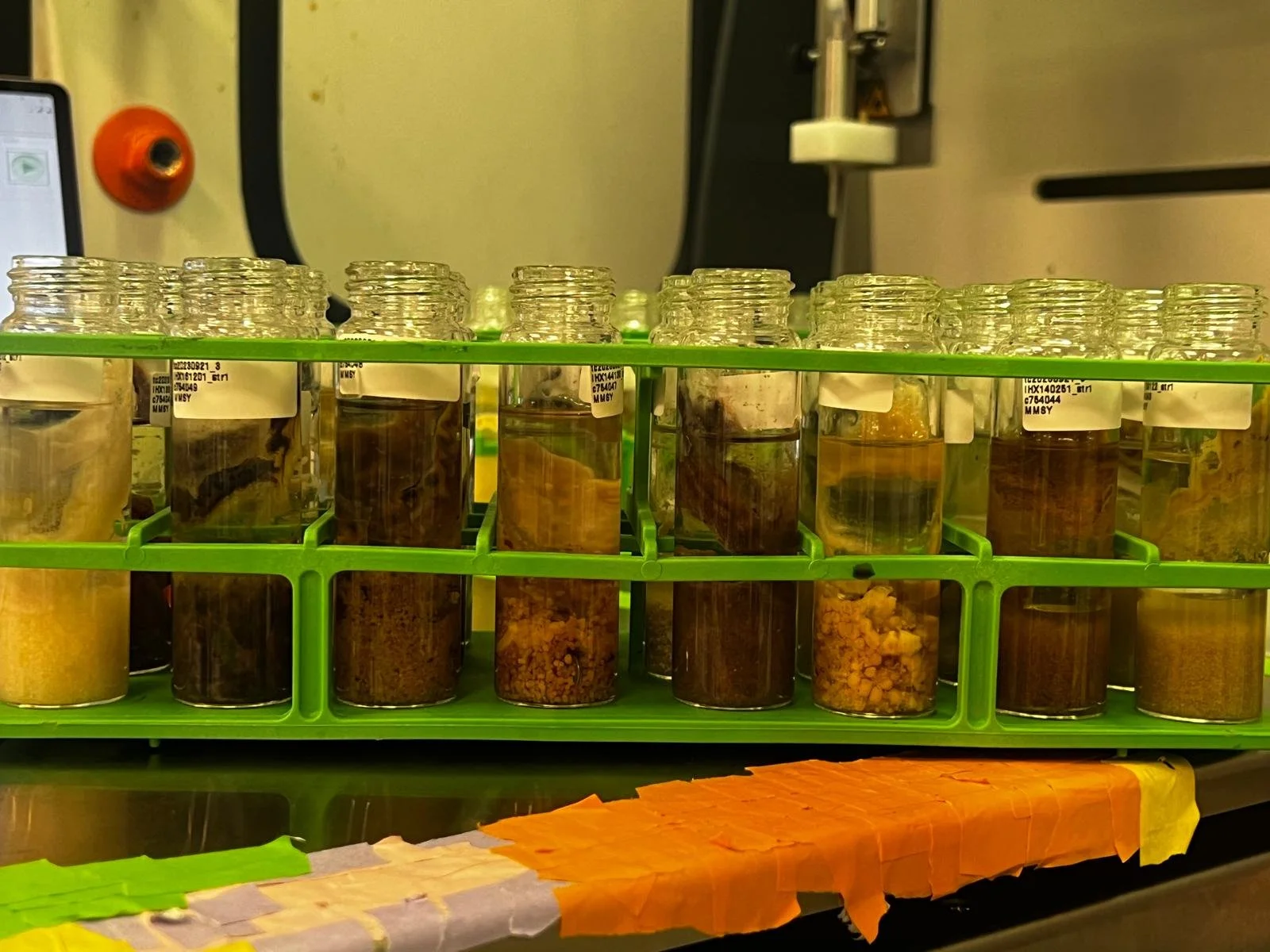

Picture of XY filler: testing different media dispense

Another robot I worked with called Mantis is used mostly for micro dispense great for mRNA Vaccine delivery.

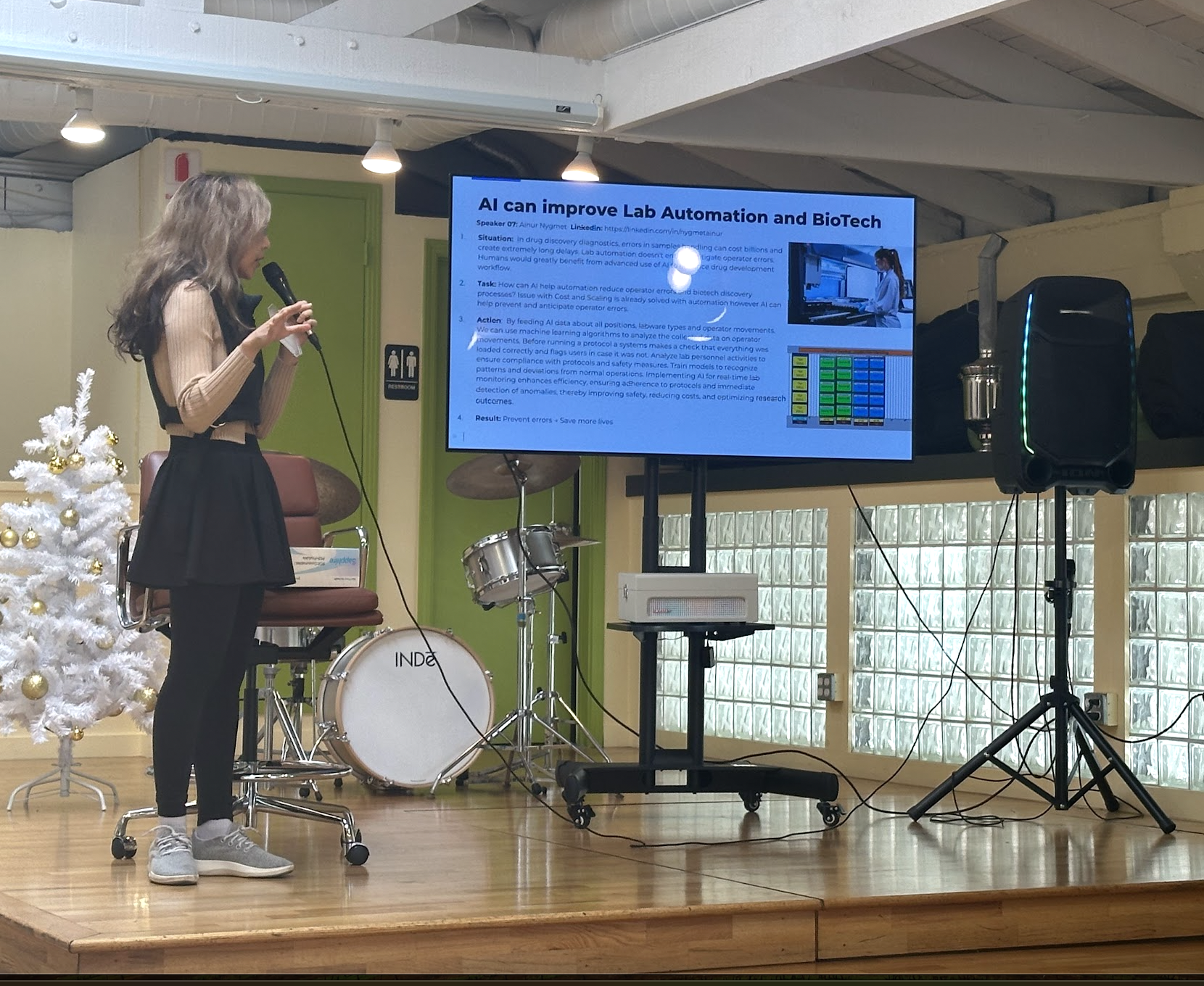

A year ago I gave a workshop at BioPunk Society in SF about Lab Automation and SilkRoad Innovation Hub in Palo Alto during Tech Crunch Week. I enjoy teaching people how to use robots and also running interactive workshops.

Video of a Hamilton Robots average robots costs 100-300k

At Hexagon, as well as other companies I worked for, we had a Workcell. What is a Workcell, you may ask? It’s typically a robotic piece of hardware integrated with automation systems, designed to streamline repetitive tasks, enhance precision, and ensure safety in laboratory or industrial workflows. Most Workcells, even in leading companies like Ginkgo Bioworks, often utilize HighRes Biosolutions hardware, with Cellario being the software of choice to operate and manage these systems efficiently. I have a special Certification to operate it it usually costs 7.5k.

To verify that XY filler was dispensing the correct amount of liquid I tested it on over 1000+ bottles with different types of media.

After dispensing from the XY filler the next step was to get the media out and dispense them into the plates. Below you can see how I tought it on the robot and developed a method for it on Hamilton and then ran it with real samples on a robot.

Here’s the fully consolidated and grouped list of methods I developed:

Cell Culture

Dilution Plating

Electroporation Transformation

Plasmid Prep

Plating

Chemical Genetics

Aliquotting

Colony Hitpicking

Glycerol Stock and Pooling

Growth Plate Hitpicking

Inoculation from Omnitrays

PCR Setup

Pooling

qPCR Dilution and Setup

Chemistry

LCMS Multiplex Hitpicking

Drug Discovery

NPL Dilution

NPL Hitpicking

NPL Onboarding

Forward Genetics

6 Cell Dispense

24 Well Cell Dispense

24 Well Compound Dispense

WGS (Whole Genome Sequencing)

gDNA Normalization

Library Amplification Hitpicking

Library Normalization

Library Pooling

qPCR Dilution

Fungen

gDNA Extraction

Index Primer

Index Primer Stamp

Frag Prep

Amplicon Normalization

Bead Purification

Lightbench Size Selection

PCR Setup (old)

PCR Setup (plates)

PCR Setup

FragAmp

Channel-based Bead Purification

Lightbench Analytics

NGS (Next-Generation Sequencing)

DNA Addition

Double Sided Bead Clean

High Volume Bead Purification

Normalization

Pooling (384)

Pooling

PlasMod

Deletion HitPicking

Ligation

Plasmid Pick and Norm

PlasMORE

Dilution 1 100 Preparation

Dilution Plating

Fragment Batch Normalization

Hitpicking (384)

Hitpicking

PCR to VB Dilution Hitpicking

Plate CherryPick

Plate Dilution

Plate Resuspension

Resuspension

Quantification

Lunatic Stamp

Reagent Prep

PCR Bead Dispense

Yeast Plasmid Extraction

Standard Parts

Normalization and Aliquot

Post PCR Pooling

Secondary Pooling

Synthetic DNA

Consolidation Normalization

Dilution

Resuspension

Tools

Glycerol Stock Prep

IDT VB Plate Processing

IDT VB Plate Stamping

Lightbench Quantification

Pico Hitpicking

Plate to Tube Hitpick Transfer

Reagent Dispense

Tip Consolidation

Volume QC

Volume Verification

Yeast

Amplicon Hitpicking

Backbone Digestion

Backbone Heat Shock

Backbone Normalization and Aliquot

Bead Extraction

Transformation